废弃物管理

The IC designed and developed by Nuvoton Technology as well as the components and products produced by foundry, are provided to customers for purposes of electronic product assembly and sales. The failure repairs, parts replacement, or disposal of the electronic products are carried out by the customers. Regarding the waste generated in the production of components and products at Nuvoton Technology, source reduction and enhanced waste recycling are adopted within the organization to reduce the environmental impact of production. Also, we ensure the compliance of outsourced waste disposal services as well. Hence, we fulfill our responsibilities in both generation and sources of wastes.

The waste management strategy at Nuvoton Technology is“waste minimization and maximization of resource recycling.”Waste classification and reduction management at the source is practiced so as to minimize wastes generated per unit product and maximize wastes turning into resources. Material use extension at the source of production, optimization of production operations, recycling of packaging materials, and other reduction programs are promoted, along with ongoing assessment for waste recycling.

Nuvoton engages in waste classification and collection, storage and management, outsourced removal/disposal, and waste declaration pursuant to internal “Waste Disposal Management Procedures.” The on-plant audits precisely capture the output of each process so as to improve the process, reduce waste, and ensure legal/regulatory compliance. Legal waste cleaning and recycling service providers approved by government are selected to handle the wastes generated. Before entrusting the wastes, the service providers are verified as to whether the cleaning and recycling methods adopted thereby are appropriate and are required to pass inspection procedures. Also, the clearance status is continuously monitored. There was no report of Nuvoton being fined or otherwise punished for violation of environmental protection laws or regulations in 2022.

Each year, in line with the hazard of wastes, the amount generated, and the results of the previous audit score, the severity of the risk of impact on the environment and the level of likelihood thereof are assessed. Then, the severity and likelihood of risk matrix and regulatory requirements are employed to determine the frequency of waste clearance service provider audit. The annual waste service provider audit plan is formulated every 1 to 3 years to check the clearance service providers’ on-plant operation as well as its treatment/reuse facility operation. Also, the GPS trajectories check is performed immediately after service providers’ removal of wastes to ensure that wastes are properly disposed, so as to effectively manage the risks of waste disposal. A total of 26 audits were conducted in 2022. There was no service provider subject to suspension of cooperation due to violations of laws and regulations or relevant regulations, and no waste-related inappropriately handled incident was reported.

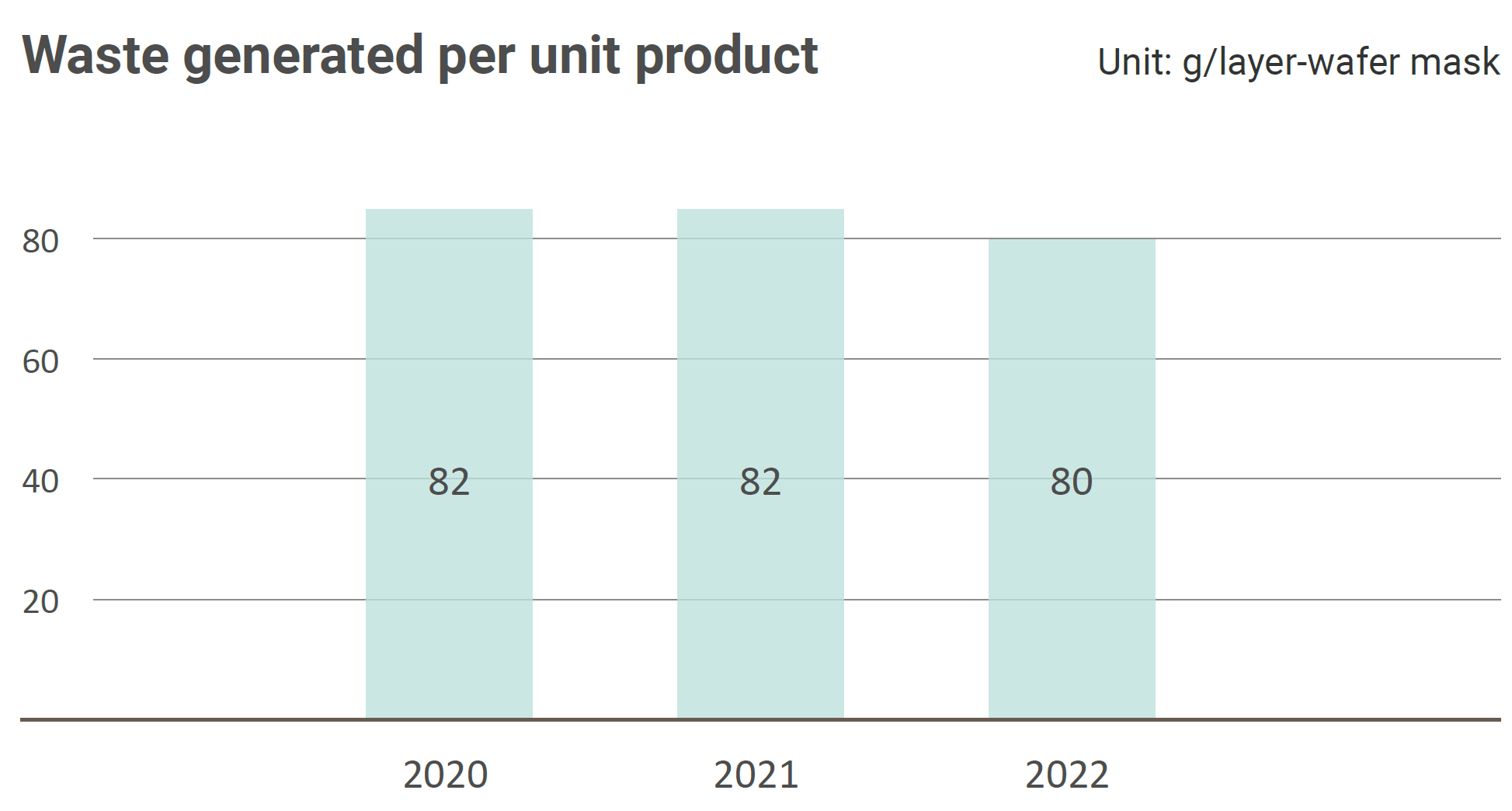

Nuvoton Technology does not have waste input or output. Reuse is prioritized for waste disposal. The wastes that cannot be reused are disposed by means of incineration and landfill. The total waste generated in 2022 was 813 metric tons. The wastes can be classified into general industrial waste (including recycling waste and domestic waste from offices) (284 metric tons, 35%) and hazardous industrial waste (529 metric tons, 65%). The waste generated per unit product was 80 g/layer-wafer mask, which is less than that of 2021. The amount reused (recycled included) was 596 metric tons (74%), the amount incinerated about 198 metric tons (24%), and the amount for landfill treatment with a higher environmental burden 19 metric tons (2%), demonstrating the prioritization of eco-friendly methods for waste disposal by the Company. In order to maximize the resource recycling via entrusted reuse, it planned in 2022 to add another dedicated pipeline for waste sulfuric acid recycle of manufacturing machine, which is expected to improve on the recovery waste sulfuric acid upon project completion in 2023.

粤公网安备 44030502010001号

粤公网安备 44030502010001号