High-Channel AFE Products for 800V+ Battery Systems: Response and Safety • Nuvoton Technology Analog Front-End Products – Industry's Highest 25 Channels

With major automotive markets such as China moving toward 800V, and potentially even 1000V large battery platforms, driven by considerations like long range and efficient fast charging, large-scale containerized energy storage systems are also continually increasing battery management system voltages to 1500V platforms and beyond, following improvements in thermal management. Both key lithium battery markets are experiencing a trend toward high-voltage, multi-series large battery packs.

This increasing market demand and application trend presents challenges for battery management system (BMS) designers in terms of effectively managing larger battery stacks or more series-connected batteries.

The challenge brings various specific issues to consider. For instance, battery management topologies can no longer be simply categorized as centralized or distributed; instead, a hybrid topology that primarily adopts a distributed approach while incorporating the advantages of a centralized one is more appropriate. Since there are too many topics involved and limited space, this time, we will share our perspectives focused on system response speed and related safety considerations.

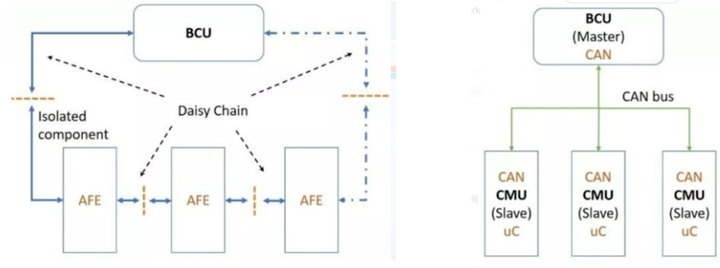

Historically, due to the actual series count of battery packs and the cost-performance considerations after balancing safety, most automotive platforms under 400V and energy storage systems below 800V have favored centralized topologies. These systems use daisy-chain communication as a bridge between each CMU (Cell Monitoring Unit), with the BCU (Battery Control Unit) performing battery cell monitoring and management.

Centralized Distributed

The advantage of centralized systems is simplicity, ease of management, and cost-effectiveness. However, regarding safety, especially regarding response speed in battery failure, centralized systems are not as fast as distributed systems. Distributed systems, however, suffer from being complex, having more management layers, and being less cost-effective. Is it possible to combine the advantages of both while minimizing their weaknesses? By constructing 800V+ platforms based on high-string battery packs (20+ series), communication risk points and safety risks can be minimized, while improving daisy-chain communication speed to enhance response time. This approach maximizes the cost-effectiveness of centralized systems while integrating hierarchical management from distributed systems.

Previously, centralized systems were undoubtedly the better option when battery strings were lower. The marginal effects caused by battery failure could be controlled through the MCU's battery safety link and wide-area diagnostics, satisfying safety requirements. However, as battery voltage platforms increase and the number of battery strings grows rapidly, response speed and safety inevitably decrease. Suppose we want to improve response time and safety without compromising cost-effectiveness. In that case, we must enhance the response speed of the centralized architecture while reducing the number of layers in distributed management.

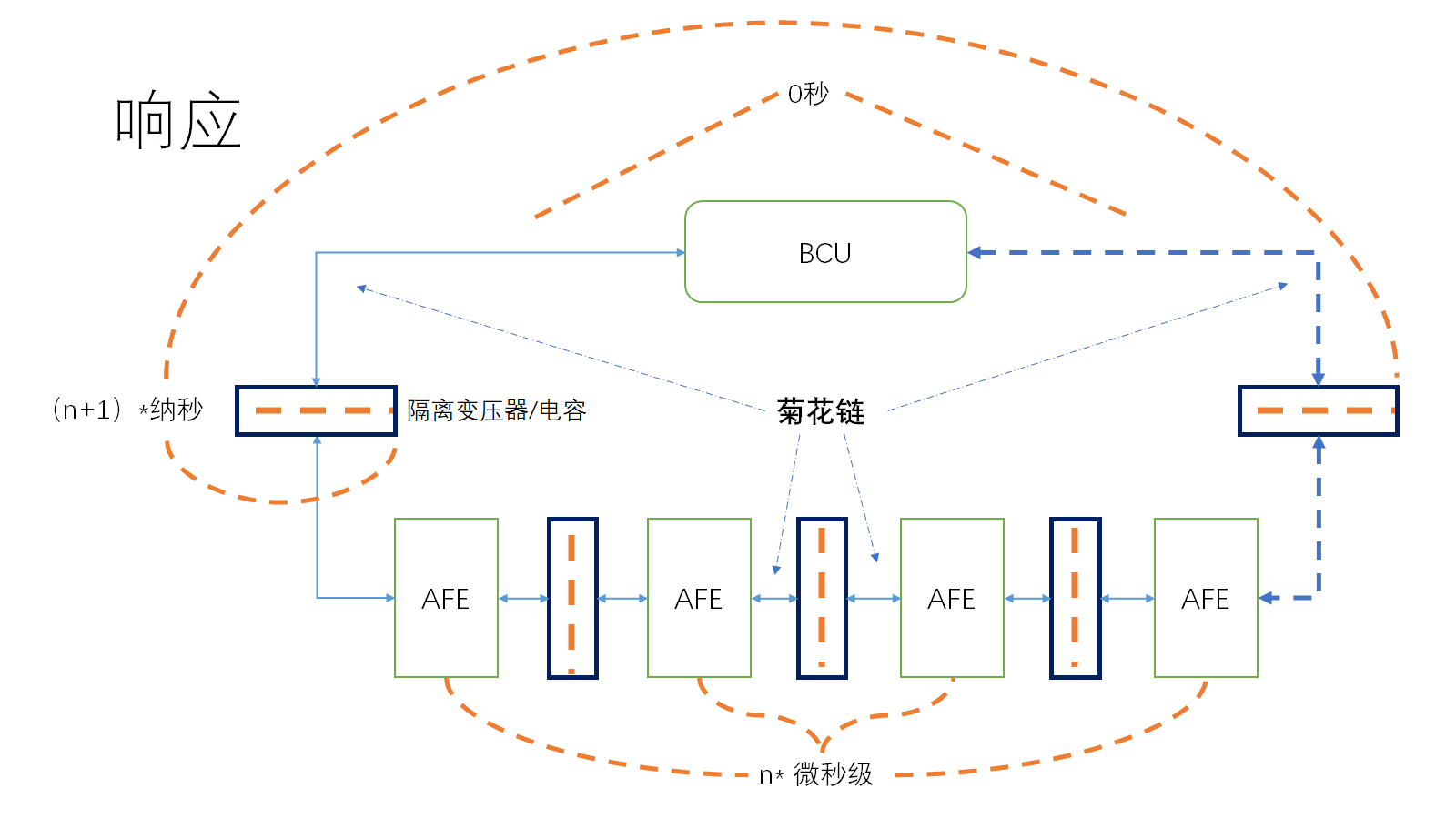

Now, let's look at the factors that affect response speed in centralized systems and how to improve them.

The number of battery cells: Once the voltage of the BMS (Battery Management System) platform is determined, the total number of series-connected battery cells is fixed. As long as the AFE's collection channels are not excessively wasted (unused), the overall collection time is fixed and has minimal impact on response speed. If the AFE's collection speed is increased, reducing the overhead of collection time can improve the response speed.

Next, the time spent on AFE communication: The time spent on communication by the AFE is mainly related to the current propagation speed, isolators (transformers/capacitors), and the AFE itself. The current speed in a wire is close to the speed of light, so the delay is negligible. Currently, mainstream isolators have signal delays in the nanosecond (ns) range, typically not exceeding 100ns, which can also be ignored. Therefore, the AFE’s communication time is another factor affecting response. Reducing the number of AFEs used in the system, while improving communication speed, can also improve the response speed.

Finally, MCU communication speed: The communication speed of the MCU (Microcontroller Unit) depends on its clock frequency and communication interfaces. Once the selection is made, the time overhead is essentially fixed.

From the simple analysis above, it can be concluded that the MCU has a fixed time overhead, improvements in isolator nanosecond-level delays are minimal, and reduced time spent on AFE communication can significantly enhance system response and safety.

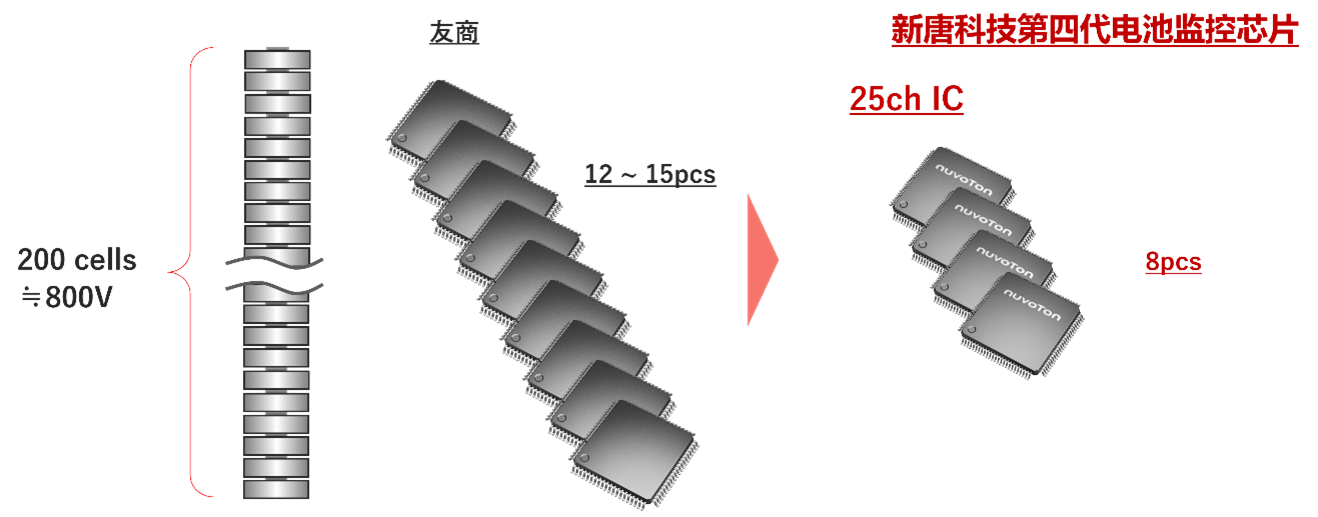

Among the measures to improve system response, reducing the number of AFEs used will bring the most significant improvement. The next step is improving the communication speed and safety of the AFE daisy chain, followed by improvements in the isolators and wiring associated with the daisy chain.

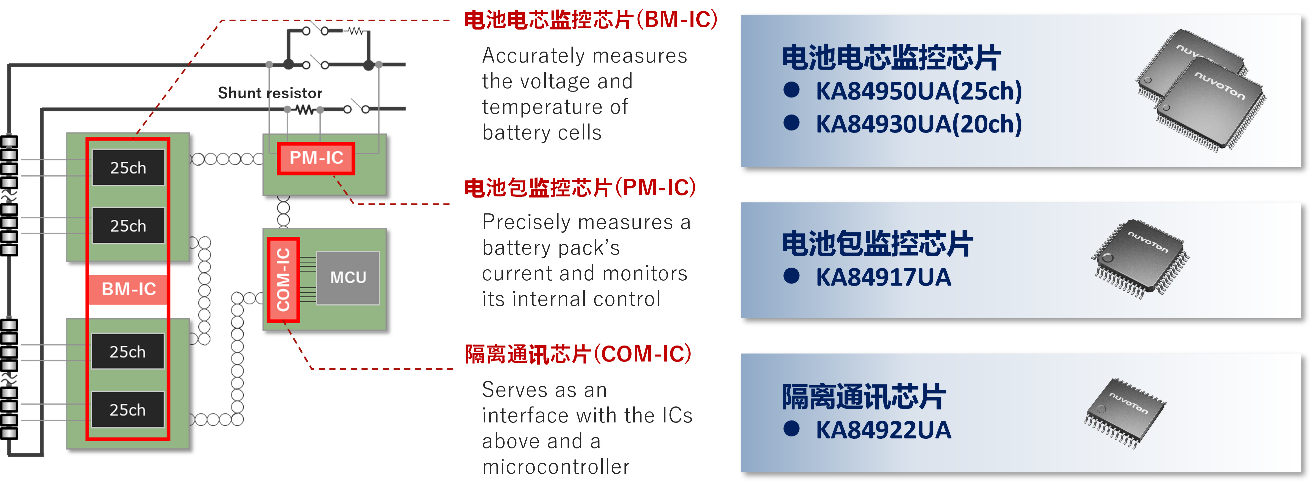

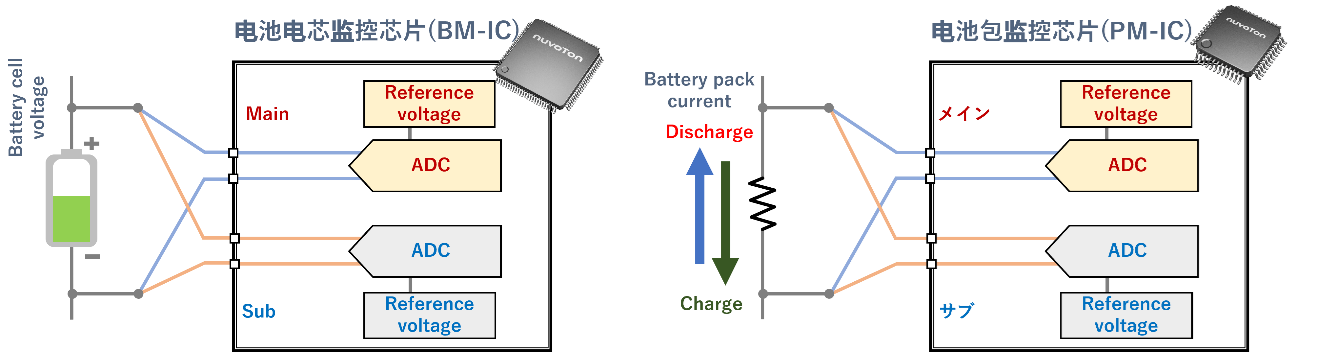

Nuvoton Technology has recently launched the industry's highest 25-series fourth-generation battery monitoring IC series. This series includes a set of chips, including the Battery Monitoring IC (BM-IC), Battery Pack Monitoring IC (PM-IC), and Isolated Communication IC (COM-IC). Below is a simplified BMS system architecture and corresponding product models.

For more information on product features, please visit Nuvoton Technology's website: https://www.nuvoton.com

Nuvoton’s BM-IC can manage up to 25 series-connected battery cells. For an 800V battery system platform, the number of AFEs used will be reduced by 35% to 45%. Meanwhile, Nuvoton's AFE products integrate high-precision ADCs with a temperature range of 1.5mV accuracy and a conversion rate of up to 20µs/channel. The reduction in the number of AFEs by 35% to 45% and the increase in collection speed mean that the system response speed will be improved. Considering the interaction between system failure rates and component failure rates, the reduction in AFEs will also reduce the number of safety nodes in the system, thus lowering the risk of system failure. Additionally, with fewer AFEs, the BOM cost will decrease, improving cost-effectiveness.

Furthermore, Nuvoton's BM-IC features daisy-chain communication with a maximum communication speed of up to 4MHz, which is approximately a 60% improvement compared to the 2.5MHz used in current mainstream market applications.

Lastly, Nuvoton is committed to high safety standards in every generation of battery monitoring products. It employs technologies such as SOI (Silicon On Insulation) high-voltage processes, fully redundant designs, and bi-directional daisy-chain communication. These technologies are also implemented in the latest fourth-generation battery monitoring ICs. These innovations significantly enhance the robustness of the AFE products and the overall system, improving system response and safety.

High-channel AFE products are ideal for balancing the safety, system response, and cost-effectiveness of 800V automotive or 1500V containerized energy storage battery platforms. Nuvoton is the only company in the industry to offer AFE products supporting over 20 series, with over 10 years of real-world application experience.

Nuvoton looks forward to in-depth collaboration with industry clients to provide safe, stable, cost-effective battery products. For further consultation, please visit Nuvoton's website or contact a Nuvoton distributor.

粤公网安备 44030502010001号

粤公网安备 44030502010001号